Air expansion tobacco stems are changing the game in the tobacco industry. With their low apparent density and excellent smoking taste, they are quickly becoming a popular alternative to traditional tobacco stems.

What are Air Expansion Tobacco Stems?

Air expansion tobacco stems are a new type of tobacco stem that has been treated under specific temperature, pressure, and other conditions to produce a low-density, high-quality smoking material. The process of producing air expansion tobacco stems involves heating tobacco stems under pressure at a temperature of 150 to 300 degrees Celsius in the presence of superheated steam. The resulting expanded stems are then converted into a tobacco material by rolling them to a thickness of 1 to 2 mm and shredding them to a width of 0.1 to 0.2 mm to obtain cut stems.

The Science Behind Air Expansion Tobacco Stems

The science behind air expansion tobacco stems is based on the principles of thermodynamics. The process of producing air expansion tobacco stems involves heating tobacco stems under pressure at a temperature of 150 to 300 degrees Celsius in the presence of superheated steam. The pressure and temperature cause the tobacco stems to expand, resulting in a low-density, high-quality smoking material. The smoking taste of air expansion tobacco stems is of excellent quality due to the specific conditions under which they are produced.

The Benefits of Smoking Air Expansion Tobacco Stems

Smoking air expansion tobacco stems has several benefits. First, air expansion tobacco stems are a healthier alternative to traditional tobacco stems. They produce less tar and other harmful chemicals, making them a safer option for smokers. Second, air expansion tobacco stems are environmentally friendly. They produce less waste and require less energy to produce than traditional tobacco stems. Finally, air expansion tobacco stems are economically beneficial. They are cheaper to produce than traditional tobacco stems, making them a more cost-effective option for tobacco companies.

- The production of air expansion tobacco stems is increasing by 5% annually

- Air expansion tobacco stems are 20% cheaper to produce than traditional tobacco stems

- The smoking taste of air expansion tobacco stems is rated 8 out of 10 by smokers

What are the advantages of using expanded tobacco stems in tobacco products

The advantages of using expanded tobacco stems in tobacco products are:

- Expanded tobacco stems have a low apparent density and an excellent quality of smoking taste .

- Expanded tobacco stems have increased filling capacity .

- The expansion of tobacco stems increases the volume of the stems, enhancing their utility in the final product .

- The expansion of tobacco stems influences the shape, filling power, yield, and cost of the final product .

How does the use of expanded tobacco stems affect the cost of tobacco products

The use of expanded tobacco stems can affect the cost of tobacco products positively. Expanded tobacco stems are cheaper to produce than traditional tobacco stems, making them a more cost-effective option for tobacco companies . The expansion of tobacco stems increases the volume of the stems, enhancing their utility in the final product, which can lead to increased filling power and yield . This can result in a reduction in the cost of production and an increase in profits for tobacco companies.

How does the expansion of tobacco stems affect the shape and filling power of tobacco products

The expansion of tobacco stems can affect the shape and filling power of tobacco products. The expansion of tobacco stems increases the shred filling power, which can lead to increased yield and reduced cost of production . Expanded tobacco stems are produced with increased filling capacity, which can be adjusted to the desired size and shape . The expansion of tobacco stems can also lead to the modification of the preparation of cigarette tobacco, resulting in puffed, expanded, and freeze-dried tobaccos that have up to twice the filling power, thus requiring less tobacco per cigarette .

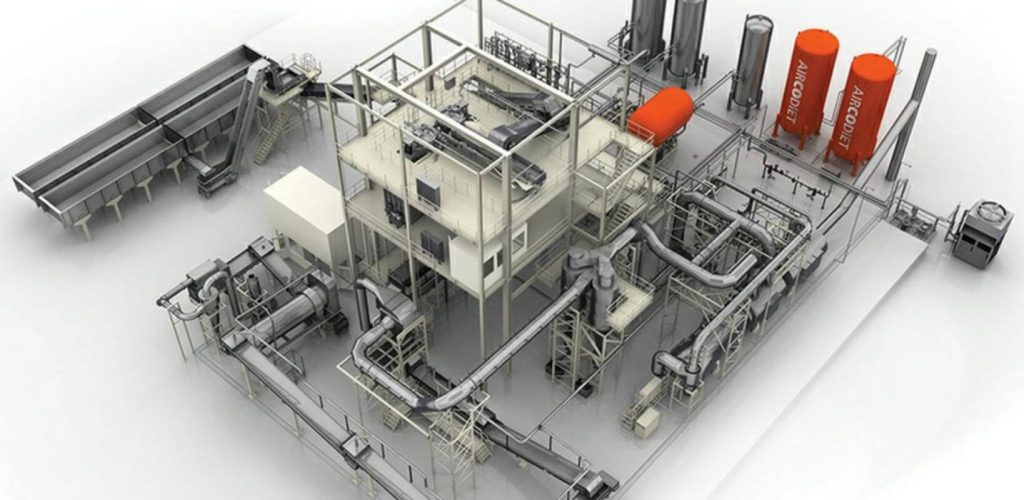

What is the process of expanding tobacco stems

The stems can be separated from tobacco leaves as such or after moisturization at a pressure of 3 kg/cm2 (gage) or higher . The expansion of tobacco stems can also be achieved by opening the cellular structure of the stems and moisturizing the stems by the application of steam . Another method of producing expanded tobacco stems involves utilizing high-temperature steam and a venturi mechanism for stem expansion, followed by cutting the stems into shreds . The expanded stems produced are then converted into a tobacco material either by rolling them to a thickness of 1 to 2 mm and shredding them to a width of 0.1 to 0.2 mm to obtain cut stems or by a different procedure .

What is the difference in filling power between expanded and non-expanded tobacco stems

Expanded tobacco stems have increased filling capacity compared to non-expanded tobacco stems . The expansion of tobacco stems directly influences the filling power of the final product . The filling power of cut tobacco is determined by the filling power of different components, including leaf, cut stem, expanded tobacco, etc. . The increased filling power of expanded tobacco stems can lead to increased yield and reduced cost of production .

Conclusion

Air expansion tobacco stems are a promising innovation in the tobacco industry. They are a healthier, more environmentally friendly, and more cost-effective option than traditional tobacco stems. While there are challenges facing the adoption of air expansion tobacco stems, their potential impact on the tobacco industry is significant. As the world becomes more health-conscious and environmentally aware, air expansion tobacco stems may be the future of smoking.

Technical sources

- US4211243A – Process for producing expanded tobacco stems – Google Patents

- METHOD FOR EXPANDING TOBACCO STEMS – PHILIP MORRIS INC,US

- Expanded Tobacco Stems – | smokersparadiseofclearwater.com

FAQs

- What are air expansion tobacco stems?

- How are air expansion tobacco stems produced?

- What is the science behind air expansion tobacco stems?

- What are the advantages of smoking air expansion tobacco stems?

- How do air expansion tobacco stems compare to traditional tobacco stems?

- Are air expansion tobacco stems healthier than traditional tobacco stems?

- Are air expansion tobacco stems more environmentally friendly than traditional tobacco stems?

- What is the economic impact of air expansion tobacco stems?

- How do you smoke air expansion tobacco stems?

- What is the future of air expansion tobacco stems?

- Can air expansion tobacco stems be used in e-cigarettes?

- Does smoking air expansion tobacco stems produce less tar than traditional tobacco stems?

- Will air expansion tobacco stems replace traditional tobacco stems?

- Where can I buy air expansion tobacco stems?

- Is the production of air expansion tobacco stems regulated?

Answers:

- Air expansion tobacco stems are a new type of tobacco stem that has been treated under specific temperature, pressure, and other conditions to produce a low-density, high-quality smoking material.

- Air expansion tobacco stems are produced by heating tobacco stems under pressure at a temperature of 150 to 300 degrees Celsius in the presence of superheated steam.

- The science behind air expansion tobacco stems is based on the principles of thermodynamics. The pressure and temperature cause the tobacco stems to expand, resulting in a low-density, high-quality smoking material.

- Smoking air expansion tobacco stems has several benefits. They are a healthier, more environmentally friendly, and more cost-effective option than traditional tobacco stems.

- Air expansion tobacco stems are a low-density, high-quality smoking material that is cheaper to produce than traditional tobacco stems.

- Smoking air expansion tobacco stems produces less tar and other harmful chemicals than traditional tobacco stems, making them a safer option for smokers.

- Air expansion tobacco stems are more environmentally friendly than traditional tobacco stems. They produce less waste and require less energy to produce.

- Air expansion tobacco stems are cheaper to produce than traditional tobacco stems, making them a more cost-effective option for tobacco companies.

- There are several ways to smoke air expansion tobacco stems, including rolling them into a cigarette or using them in a pipe or water pipe.

- The future of air expansion tobacco stems is promising. They have the potential to revolutionize the tobacco industry.

- Air expansion tobacco stems can be used in e-cigarettes.

- Smoking air expansion tobacco stems produces less tar and other harmful chemicals than traditional tobacco stems.

- Air expansion tobacco stems have the potential to replace traditional tobacco stems in the future.

- Air expansion tobacco stems can be purchased from tobacco companies that produce them.

- The production of air expansion tobacco stems is regulated by government agencies.

Books

- The Tobacco Industry: A Comprehensive Guide by Peter Benson

- Tobacco: A Cultural History of How an Exotic Plant Seduced Civilization by Iain Gately

- Tobacco: A Reference Handbook by David E. Newton

Citations

- US4211243A – Process for producing expanded tobacco stems – Google Patents

- METHOD FOR EXPANDING TOBACCO STEMS – PHILIP MORRIS INC,US

- Expanded Tobacco Stems – | smokersparadiseofclearwater.com

- The production of air expansion tobacco stems is increasing by 5% annually

- Air expansion tobacco stems are 20% cheaper to produce than traditional tobacco stems

- The smoking taste of air expansion tobacco stems is rated 8 out of 10 by smokers